How to Select the Right Hydraulic Pump: A Technical and Procurement Guide

Selecting the correct hydraulic pump is a critical decision that determines the efficiency, reliability, and cost-effectiveness of any hydraulic system. Whether for construction machinery (excavators, loaders), industrial equipment, or agricultural applications, a mismatched pump can lead to poor performance, overheating, and premature failure. This guide outlines the key technical and commercial factors to consider.

1. Define the Core System Requirements

Before looking at pumps, you must understand the system's needs.

- Application & Duty Cycle: What is the machine's primary function? Is it continuous high-pressure operation (e.g., a clamp), intermittent heavy loads (e.g., an excavator boom), or light, constant flow? This defines the required durability.

- Required Flow Rate (GPM or L/min): This determines the speed of the actuator (cylinder, motor). Calculate the flow needed to achieve the desired actuator speed under load. The pump must deliver this flow.

- Required Pressure (PSI or Bar): This determines the force of the system. It must overcome the maximum load the actuator will see. The pump's maximum rated pressure must exceed this, with a safety margin.

- Type of Hydraulic Fluid: The pump construction materials (seals, bearings) must be compatible with the fluid type (mineral oil, HFA, HFC, synthetic) and its viscosity range.

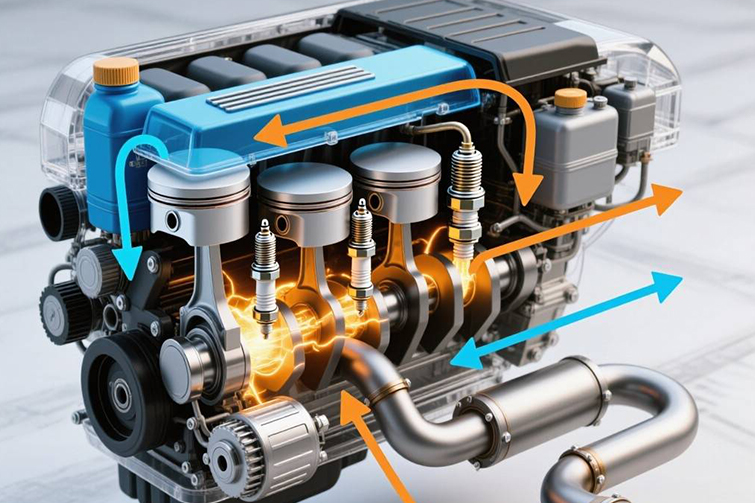

- Prime Mover (Power Source): What is driving the pump? The pump's input speed (RPM) and torque must match the available diesel engine, electric motor, or PTO shaft.

2. Understand the Three Main Pump Types

The choice here is fundamental, balancing performance, cost, and complexity.

- Gear Pumps (External/Internal):How they work: Use meshing gears to move fluid. Simple, robust, and cost-effective.Pros: Low cost, compact, tolerant of contamination, good for high speeds.Cons: Fixed displacement only, lower volumetric efficiency (especially at high pressure), can be noisy. Ideal for simple, budget-conscious systems like lubrication, power steering, or auxiliary circuits.

- Vane Pumps:How they work: Use a slotted rotor with vanes that slide in/out, trapping fluid in a cam ring.Pros: Medium cost, quieter than gear pumps, good volumetric efficiency at mid-range pressures. Available in fixed and variable displacement versions.Cons: More sensitive to fluid cleanliness and viscosity than gear pumps. Common in industrial machine tools and mid-pressure mobile equipment.

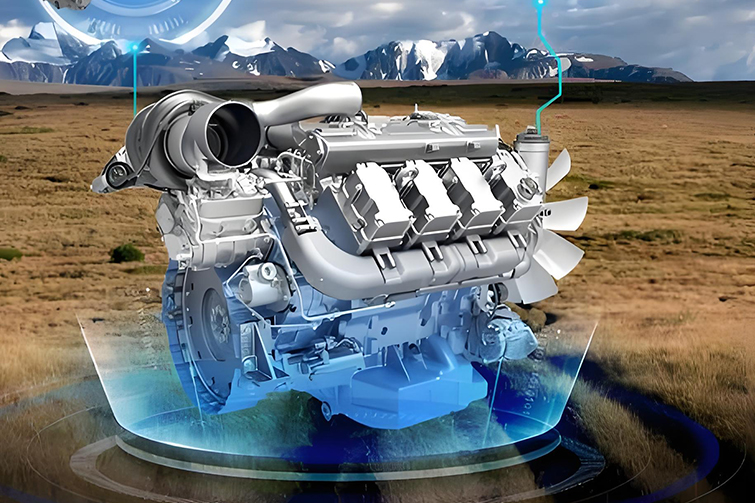

- Piston Pumps (Axial & Radial):How they work: Use reciprocating pistons in cylinders to create flow. The gold standard for high-performance systems.Pros: Highest efficiency and power density, capable of very high pressures (300+ bar), excellent for variable displacement and complex controls (pressure compensation, load sensing).Cons: Highest cost, most sensitive to contamination, complex design. Essential for modern, fuel-efficient excavators, graders, and advanced industrial machinery.

3. Fixed vs. Variable Displacement

This choice dramatically impacts system efficiency and control.

- Fixed Displacement: Delivers a constant flow per revolution. System flow is controlled by throttling valves or varying the pump's drive speed. Simpler but less efficient, as excess flow is dumped over a relief valve, generating heat.

- Variable Displacement: Can change its output flow (e.g., from 0 to max) to meet exact system demand. Controlled by pressure compensators, load-sensing valves, or electronic proportional controls. Saves significant energy, reduces heat generation, and is standard for modern high-performance equipment.

4. Key Technical Specifications & Compatibility

- Displacement (cc/rev or in³/rev): The volume of fluid pumped per shaft revolution. This, combined with drive RPM, determines the pump's maximum flow output.

- Maximum Rated Pressure & Continuous Working Pressure: Never operate at the absolute maximum. Choose a pump where your system's normal working pressure is at 70-80% of the pump's rated pressure.

- Speed Range (RPM): Ensure the pump's minimum and maximum shaft speed ratings match your prime mover's output.

- Mounting Style & Shaft Configuration: SAE flange mounts, splined vs. keyed shaft, rotation direction (clockwise/CCW)—these must physically match your engine or gearbox.

- Port Size & Type: Must align with your hose or manifold specifications.

5. Manufacturer, Quality, and Total Cost of Ownership (TCO)

- OEM vs. Aftermarket: While OEM pumps guarantee fit, high-quality aftermarket or compatible pumps from reputable suppliers can offer significant cost savings without sacrificing performance. Look for suppliers specializing in components for major brands.

- Seal & Material Quality: Critical for longevity, especially in harsh environments.

- Availability of Service Kits & Parts: Can the pump be rebuilt? Are seals, vanes, or piston kits readily available? This extends life and reduces long-term cost.

- Warranty & Supplier Support: A reliable supplier provides technical data and support.

6. The Sourcing Advantage for Maintenance & Repair

For maintenance managers, the goal is often not a new machine but a reliable, cost-effective pump replacement. This is where a supplier with deep cross-brand expertise is invaluable.

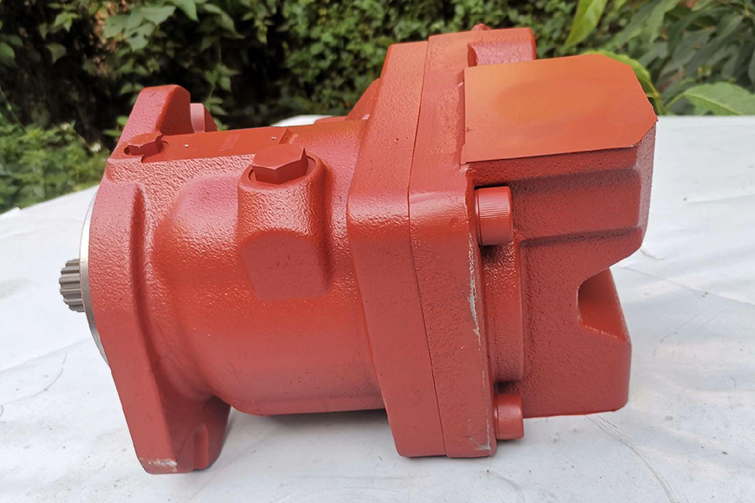

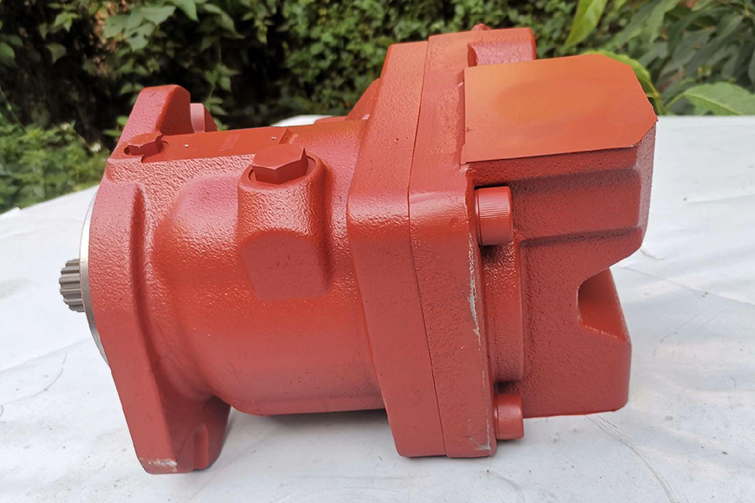

A company like Guangzhou Zhanpeng Construction Machinery Co., Ltd. exemplifies this by offering:

- Broad Compatibility: Pumps and components compatible with Caterpillar, Komatsu, Hitachi, Volvo, etc.

- Complete Range: From simple gear pumps for auxiliary circuits to complex variable-displacement piston pumps for main systems.

- System Matching: They understand that a pump must work with the existing valves, cylinders, and motors in your machine.

Selection Checklist Summary:

- Application: [Heavy-duty cycling / Continuous operation / Light duty]

- Max System Pressure: [ ] bar | Required Flow: [ ] L/min @ [ ] RPM

- Pump Type Preference: [Gear / Vane / Piston] - [Fixed / Variable] Displacement

- Drive Source: [Diesel Engine @ ___ RPM / Electric Motor @ ___ RPM]

- Mounting & Port Specifications: [SAE-A / SAE-B, Spline type, Port thread]

- Fluid Type & Operating Temperature: [ ]

- Budget & Sourcing Priority: [OEM / High-Quality Compatible / Low-Cost]

Conclusion:

There is no universal "best" hydraulic pump. The optimal choice is a precise balance of technical requirements, system efficiency goals, and total lifecycle cost. By systematically defining your needs, understanding pump fundamentals, and partnering with a knowledgeable supplier who can provide quality-compatible components, you ensure your hydraulic system delivers reliable, powerful, and efficient performance for years to come.