How to Choose the Right Engine: A Comprehensive Guide

Selecting the right engine is a critical decision that impacts performance, efficiency, cost, and longevity of your vehicle or equipment. Whether you're buying a car, replacing a motor, or sourcing one for industrial machinery, here are the key factors to consider.

1. Define Your Primary Need

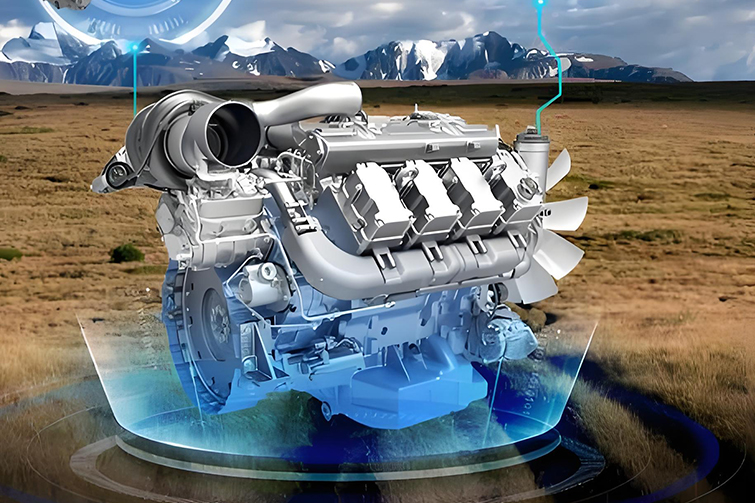

- Purpose: What will the engine power? A passenger car, a heavy-duty truck, a generator, construction equipment (like an excavator or bulldozer), or an agricultural machine? The application dictates the required power characteristics—high-speed torque for hauling, consistent RPMs for generators, or a balance for everyday driving.

- Core Priority: Identify what matters most: Fuel Economy, Raw Power (Towing/Performance), Durability/Longevity, Low Emissions, or Low Initial Cost. You often must prioritize, as excelling in one area may involve trade-offs in another.

2. Understand Engine Types & Fuel

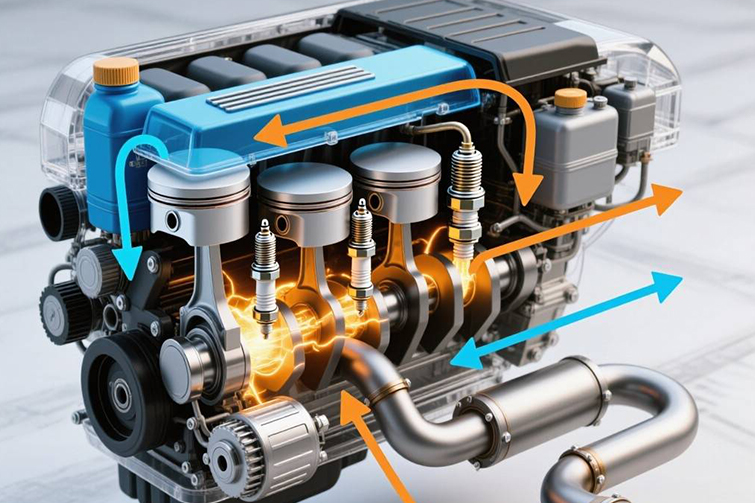

- Gasoline (Petrol): Generally provides more horsepower and smoother, quieter operation at higher RPMs. Ideal for lighter vehicles, performance cars, and applications requiring quick acceleration. Often has a lower upfront cost.

- Diesel: Delivers higher torque at lower RPMs, making it superior for towing, hauling, and heavy machinery. Diesel engines are typically more fuel-efficient for sustained load and have a longer service life, but they come with higher initial costs and more complex emissions systems.

- Alternative Fuels: Consider hybrids, electric (for full electric vehicles, the "engine" is replaced by an electric motor system), or engines compatible with biofuels/LPG if operating costs, subsidies, or environmental regulations are key drivers.

3. Evaluate Key Specifications

- Displacement & Cylinders: Measured in liters (L) or cubic centimeters (cc). Generally, larger displacement means more power and torque. More cylinders (e.g., V6, V8) often mean smoother operation than fewer cylinders (e.g., inline-3, inline-4).

- Power (Horsepower - HP/kW): Determines top speed and acceleration capability.

- Torque (Newton-meters - Nm): The rotational "pulling power." Crucial for getting a heavy load moving, towing, and climbing hills. Diesels excel here.

- Technology: Look for modern efficiency technologies like turbocharging (increases power from smaller engines), direct fuel injection, variable valve timing, and advanced emissions control systems.

4. Assess Reliability & Maintenance

- Brand/Manufacturer Reputation: Research the long-term reliability of specific engine models from brands like Cummins, Caterpillar, Yanmar (for industrial), or Toyota, Honda, Ford, etc. (for automotive). Read reviews and owner forums.

- Service Intervals & Costs: How often does it require oil changes, filter replacements, or major servicing (e.g., timing belt)? Are parts readily available and affordable?

- Complexity: Newer engines with complex emissions tech (like Diesel Particulate Filters - DPFs) may have higher potential repair costs.

5. Consider the Total Cost of Ownership (TCO)

The cheapest engine upfront is rarely the cheapest long-term. Calculate TCO:

- Purchase Price

- Fuel Consumption over its lifespan

- Estimated Maintenance and Repair costs

- Insurance (can vary by engine size/type)

- Depreciation/Resale Value (some engine types hold value better)

6. Compatibility & Integration

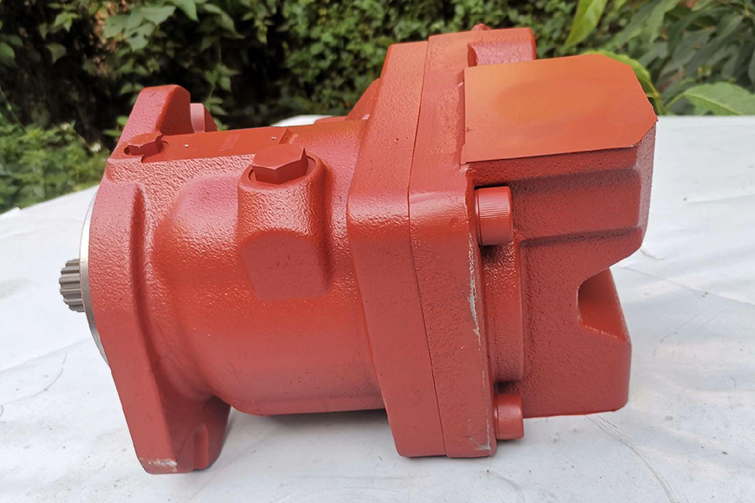

- For replacements or machinery: Exact fit is paramount. Ensure the new engine matches the mounting points, transmission bell housing, electronics (ECU compatibility), cooling system, and exhaust layout. This is where suppliers like Guangzhou Zhanpeng Construction Machinery Co., Ltd. provide value, offering compatible parts and components for a wide range of major brands.

- For vehicles: Ensure the engine option is designed for your specific chassis and model year.

7. Environmental & Regulatory Compliance

- Emissions Standards: The engine must meet the legal emissions standards (Euro, EPA, China VI, etc.) for your region. Non-compliance can lead to fines or inability to register the vehicle/equipment.

- Noise Regulations: Important for industrial and generator use in residential areas.

Conclusion

There is no single "best" engine. The optimal choice is a perfect balance of your specific requirements, budget, and operating environment. Thorough research into specifications, owner feedback, and total cost analysis is essential. For industrial and heavy equipment applications, partnering with a knowledgeable supplier who understands cross-brand compatibility—offering everything from complete engines to critical components like hydraulic pumps, turbochargers, and cylinder heads—can simplify the process and ensure you get a reliable, efficient power source tailored to your needs.