The Anatomy of an Engine: A Guide to Its Core Components

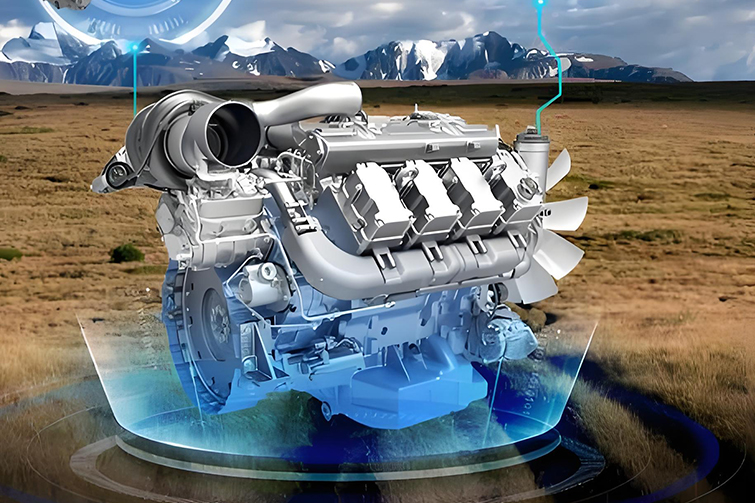

An internal combustion engine is a masterpiece of mechanical engineering, a self-contained power plant that converts the chemical energy in fuel into the rotational force that moves vehicles and machinery. While designs vary (gasoline vs. diesel, inline vs. V-shaped), most share the same fundamental components. Understanding these parts is crucial for mechanics, operators, and procurement specialists—especially when sourcing replacements from comprehensive suppliers like Guangzhou Zhanpeng Construction Machinery Co., Ltd.

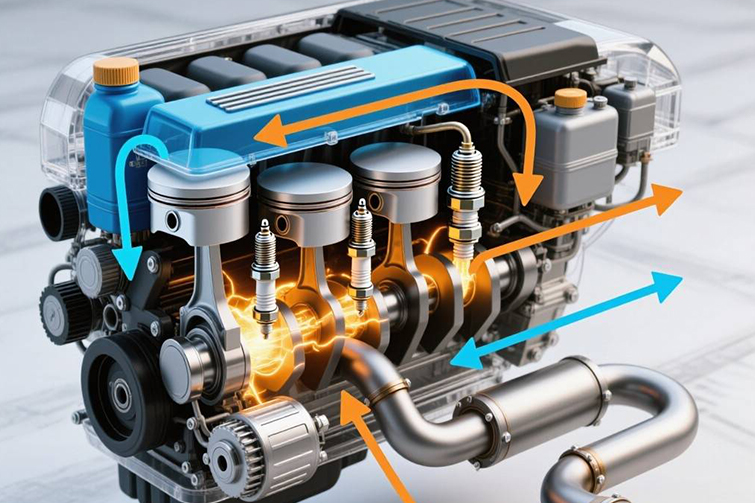

The engine can be divided into several major systems:

I. The Engine Block: The Foundation

This is the engine's main structural casting, typically made of iron or aluminum. It houses the core components.

- Cylinders: The cylindrical bores where pistons move up and down. The number of cylinders (e.g., 4, 6, 8) defines the engine's configuration.

- Crankshaft: The engine's spinning "backbone." It converts the linear (up-and-down) motion of the pistons into rotational force.

- Main Bearings: Journals that support and allow the crankshaft to rotate smoothly within the block.

- Oil Galleries: Passages machined into the block for engine oil circulation.

II. The Cylinder Head: The Command Center

Mounted atop the engine block, it seals the top of the cylinders and houses vital valvetrain components.

- Valves: Intake valves let the air-fuel mixture in; exhaust valves let burnt gases out. They are precisely opened and closed.

- Valvesprings & Retainers: These close the valves after they are opened by the camshaft.

- Camshaft: A shaft with egg-shaped lobes that controls the precise timing of valve opening/closing. It can be located in the block (OHV) or in the head (OHC/DOHC).

- Rocker Arms & Pushrods (in OHV designs): They transfer motion from the camshaft to the valves.

III. The Bottom End: The Rotating Assembly

This is the powerhouse assembly that creates motion.

- Pistons: Cylindrical components that move up and down within the cylinders, compressing the air-fuel mixture and being driven down by combustion.

- Connecting Rods ("Con Rods"): They connect the pistons to the crankshaft, transferring force.

- Piston Rings: Seals fitted into grooves on the pistons. They prevent combustion gases from leaking into the crankcase and oil from entering the combustion chamber.

- Crankshaft (housed in the block): As mentioned, the primary rotating output shaft.

IV. The Fuel & Air System: The "Diet" Management

This system meters, delivers, and mixes fuel with air.

- Fuel Injectors: Atomize and spray fuel directly into the intake manifold or cylinder (modern engines). A key replacement component.

- Intake Manifold: Distributes the air or air-fuel mixture to each cylinder.

- Throttle Body: Controls the amount of air entering the engine.

- Turbocharger/Supercharger: Force-feeds more air into the cylinders, significantly increasing power. A critical performance and replacement part.

V. The Lubrication System: The Lifeblood

Prevents metal-to-metal contact and reduces wear.

- Oil Pump: Circulates oil under pressure throughout the engine.

- Oil Sump/Pan: Reservoir at the bottom of the engine that holds the oil.

- Oil Filter: Removes contaminants from the oil to protect components.

VI. The Cooling System: The Temperature Regulator

Prevents engine meltdown by managing excess heat.

- Water Pump: Circulates coolant through the engine and radiator.

- Radiator: Transfers heat from the coolant to the outside air.

- Thermostat: Regulates coolant flow to maintain optimal engine temperature.

VII. The Ignition System (Gasoline Engines): The Spark

Creates the spark to ignite the compressed air-fuel mixture.

- Spark Plugs: Create the high-voltage spark inside the combustion chamber.

- Ignition Coils: Transform the battery's low voltage into the high voltage needed for the spark.

VIII. The Electrical & Starting System: The "Wake-Up" Call

Provides the initial power to start the engine and runs electrical accessories.

- Starter Motor: Engages with the flywheel to crank the engine.

- Alternator: Recharges the battery and powers electrical systems once the engine is running.

- Battery: Provides the initial electrical power.

IX. The Exhaust System: The Exit Path

Safely channels and treats burnt gases from the engine.

- Exhaust Manifold/Headers: Collects exhaust gases from each cylinder.

- Catalytic Converter: Reduces harmful emissions.

- Muffler: Reduces exhaust noise.

X. The Engine Management System: The Brain

The modern engine's computer network.

- Engine Control Unit (ECU): The main computer that monitors sensors (oxygen, temperature, knock) and controls actuators (fuel injectors, ignition timing) for optimal performance and efficiency.

The Procurement & Maintenance Perspective

For anyone maintaining heavy machinery or a fleet of vehicles, understanding these components is the first step in effective maintenance and smart procurement. When a part fails—whether it's a crankshaft from the bottom end, an injector from the fuel system, or a turbocharger—knowing its function allows for accurate diagnosis.

Suppliers like Guangzhou Zhanpeng Construction Machinery Co., Ltd. cater directly to this need, offering a comprehensive portfolio that covers virtually every component mentioned:

- Core Engine Parts: Cylinder Heads, Blocks, Pistons, Rings, Crankshafts.

- Supporting Systems: Oil Pumps, Water Pumps, Injectors, Turbochargers, Alternators, Starters.

- Gaskets & Seals: Essential for reassembly.

In conclusion, an engine is a symphony of interrelated parts. Its reliability depends on the quality and precise function of each component, from the largest block to the smallest piston ring. Proper maintenance and sourcing high-quality replacement parts are the keys to ensuring this symphony performs flawlessly for thousands of hours.